Cold heading sleeve Manufacturer

Hunhu hwekutonhora musoro forging process

1. Cold heading inoitwa pakamuri tembiricha.Cold heading inogona kuvandudza michina yezvikamu zvesimbi.

2. Cold heading forging process inogona kuwedzera mhindu yezvinhu.Iyo inzira yekumanikidza machining yakavakirwa papurasitiki deformation, iyo inogona kuona kushoma kucheka kana kusacheka.Chiyero chekushandiswa kwezvinhu zvese chiri mu85% pamusoro, chepamusoro chinogona kusvika 99% pamusoro.

3. Inogona kuvandudza kushanda kwekugadzira.Metal chigadzirwa deformation nguva uye maitiro ipfupi, kunyanya mune akawanda-zviteshi ekugadzira muchina ekugadzirisa zvikamu, anogona kuvandudza zvakanyanya kugadzirwa.

4. Cold forging tekinoroji inogona kuvandudza kushata kwepamusoro kwezvigadzirwa uye kuve nechokwadi chekururama kwezvigadzirwa.

Zvinodiwa zvekutonhora heading forging process pane mbishi zvinhu

1. Mushonga wemakemikari uye mechanical properties yezvinhu zvakasvibiswa zvinofanira kusangana nemitemo yakakodzera.

2. Raw zvinhu zvinofanirwa kuve spheroidized annealing kurapwa, iyo metallographic chimiro chechinhu chiri spherical pearlite level 4-6.

3. Kuoma kwezvinhu zvakasvibirira, kuitira kuti kuderedze maitiro ekuputika kwezvinhu zvakanyanya sezvinobvira uye kuvandudza hupenyu hwebasa re mold, zvinhu zvinotonhora zvinotonhora zvinodiwa kuti zvive nekuoma kwakaderera sezvinobvira kuvandudza plastiki.Kuomarara kwezvinhu zvakabikwa kazhinji kunodiwa kuve muHB110~170 (HRB62-88).

4. Iyo chaiyo yekutonhora yekudhirowa zvinhu inofanirwa kutariswa zvinoenderana nezvinodiwa chaizvo zvechigadzirwa uye maitiro.Kazhinji kutaura, chokwadi che

5. Hunhu hwepamusoro hwezvinhu zvinotonhora zvekudhirowa hunoda kuti firimu rekuzora rive rakasviba rima, uye kumusoro hakuzove nemakwara, kupeta, kutsemuka, bvudzi, ngura, oxide ganda uye gomba gomba uye zvimwe zvikanganiso.

6. Ukobvu hwese hweiyo decarburization layer munzira yekutonhora yekudhirowa zvinhu radius haifanire kudarika 1-1.5% yedhayamita yezvakagadzirwa (mamiriro chaiwo anoenderana nezvinodiwa nemugadziri wega wega).

7. Kuti uve nechokwadi chekucheka kwemhando yekugadzira inotonhora, inotonhora yekudhirowa zvinhu inodiwa kuti ive nenzvimbo yakaoma uye yakapfava core state.8. Cold-yepamusoro forging test inofanirwa kuitirwa zvinhu zvinotonhora-inodhonzwa, uye kunzwisiswa kwezvinhu kune inotonhora-kushanda kuoma kunofanirwa kuve kwakadzikira sezvinobvira, kuitira kuderedza kuwedzera kwe deformation kuramba nekuda kwekutonhora-kushanda kuoma panguva. deformation.

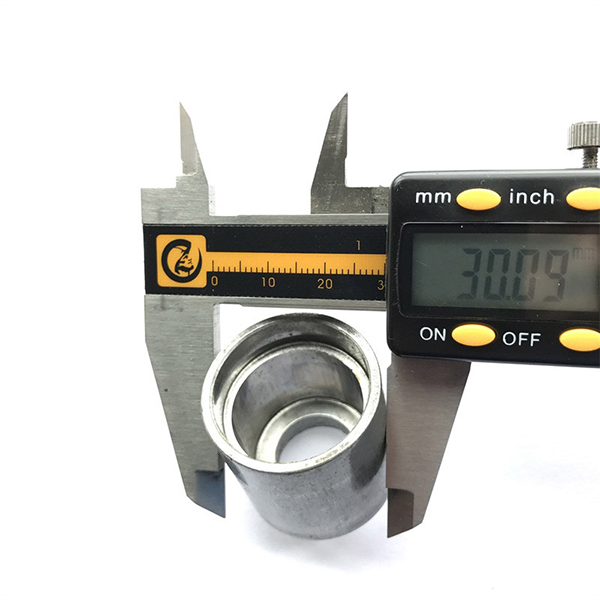

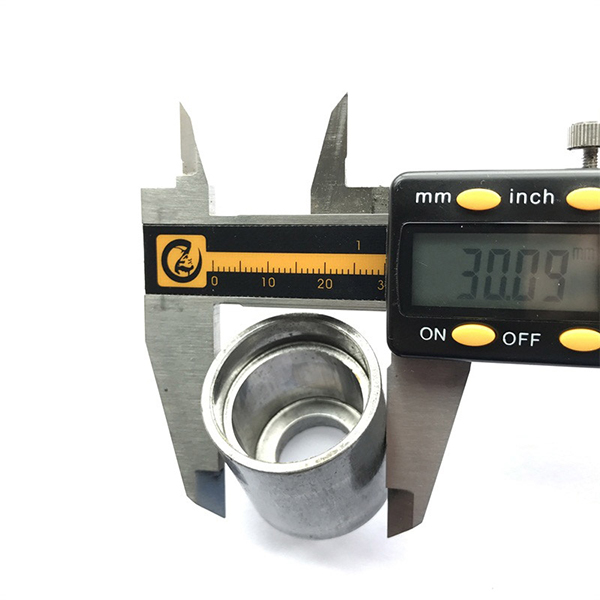

Product Display